MiSCAN 5000 - Lead Vision

Specification:

Brand |

Lead Vision - Beijing |

|

Application |

Daily chemicals, food and pharmaceuticals |

|

Applicable Materials |

Paper, Plastic film. |

|

Defect Types |

Streak, missing print, dirty spot, splash, mis-registration , color deviation, foreign objects etc. |

|

Max. Web Width |

1250 mm |

|

Max. Inspection Speed |

300 m/min |

|

Min. Defect Accuracy |

0.10 mm2 |

|

Accuracy of mis-registration |

0.16 mm |

|

Color Measurement (△E) |

>3 |

|

E-cabinet Outline |

700x700x1200 mm |

|

Power |

AC220V±10%/60Hz/16A with UPS system TBD by customer |

|

Temperature/Humidity |

0℃~40℃/ 20%~60% |

Configuration:

Qty |

Remark |

|

|

Imaging Units |

4K-RGB industrial camera * 2 |

Camera: JAI,Japan |

|

Processing Units |

processing card *1 |

Procession:Dalsa XMX,Canada |

|

Software |

MiScan 5000 Inspection software*1 |

Programmed by Lead Vision |

|

Electronic Units |

Independent Cabinet *1 |

- |

Introduction:

The solution is configured as a Japanese dual 4k camera detection system, and the configuration and accessories are all imported accessories, to ensure the stable and efficient operation of the detection system, and to ensure the accuracy of the detection of defects. Above, the technical level of the inspection system can be seen out of the ordinary, first, the detection accuracy is very high and can be adjusted according to the needs of customers, and the second is the detection accuracy of defects is very high, almost no false positives or missed detection phenomenon. The significance of the online system is to detect the defects, report the location of the attached defects in meters, first, the alarm is found in the production process, and the machine is adjusted in time to reduce continuous waste products, reduce production costs, and second, the defects can be rewound according to the number of meters. The quality of the product to the end customer can be guaranteed, thereby reducing the customer complaint rate, controlling the product quality, and improving the company's quality reputation.

Basic working principle:

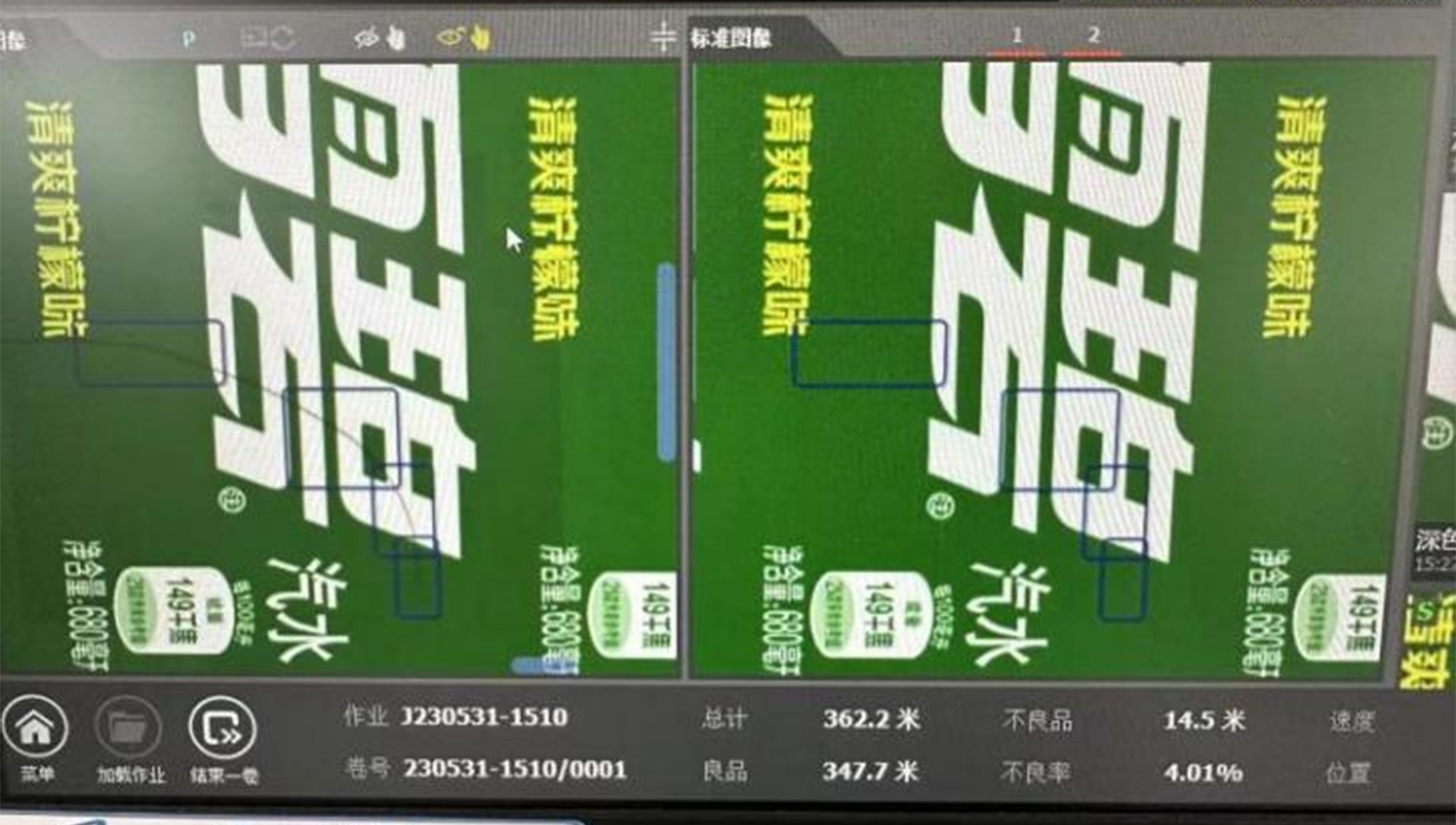

1.After running the material on rewinding machine, alldefects recorded automatically in the system.

2.You may check all the defects in the computer beside the machine.

3.Normally, it won’t too many defects. Your operator will go over all the defects one by one very quickly according to your quality standard, and to click choose which ones are acceptable and the rest ones have to be removed from the roller.

3.Once confirm the result you may running the machine backwards, and it will stop at all the defects you have chosen to remove.

4.You may use splicing table to cut off the film with defects then splice the film and continue to run.

Basic installing and feature of the system:

Function description:

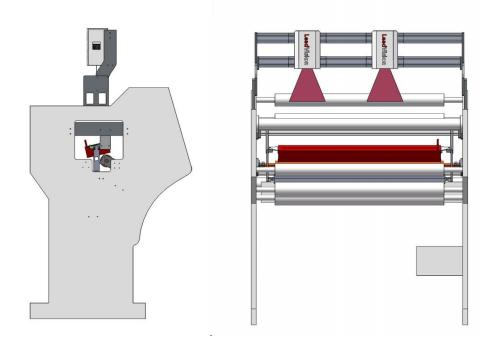

Structure:

1.The electrical cabinet includes the electrical cabinet and two monitors on the electrical cabinet, as well as the red and green acoustic-optic alarm, the industrial computer and the acquisition card, and the integrated board are all inside the electrical cabinet, with simple structure and high integration degree.

2.Using mouse and keyboard to interact with operating system.

3.The platform part includes the camera, light source, encoder, and the required fixed structural parts.

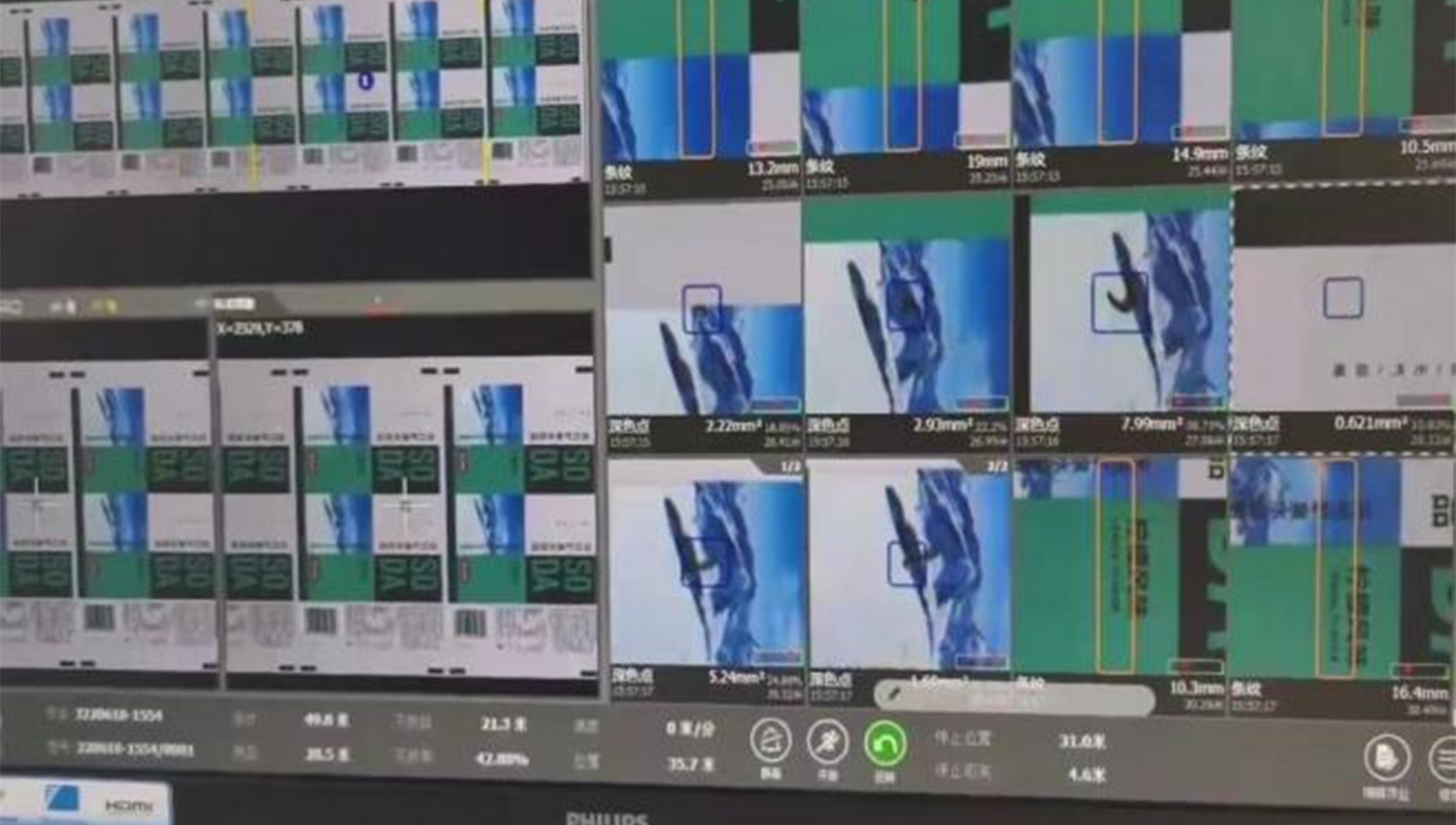

UI screen:

The strong part of Lead Vision system:

1.The image is more clear compare to the other brand.

2.Test detection accuracy 0.03mm

3.QR code inspection available.

4.Reliable in low contrastcondition

5.Missed prints can be detected

6.Chromatic aberration can be detected

7.Thelight source cab be adjust according to the application. If ECO designed.

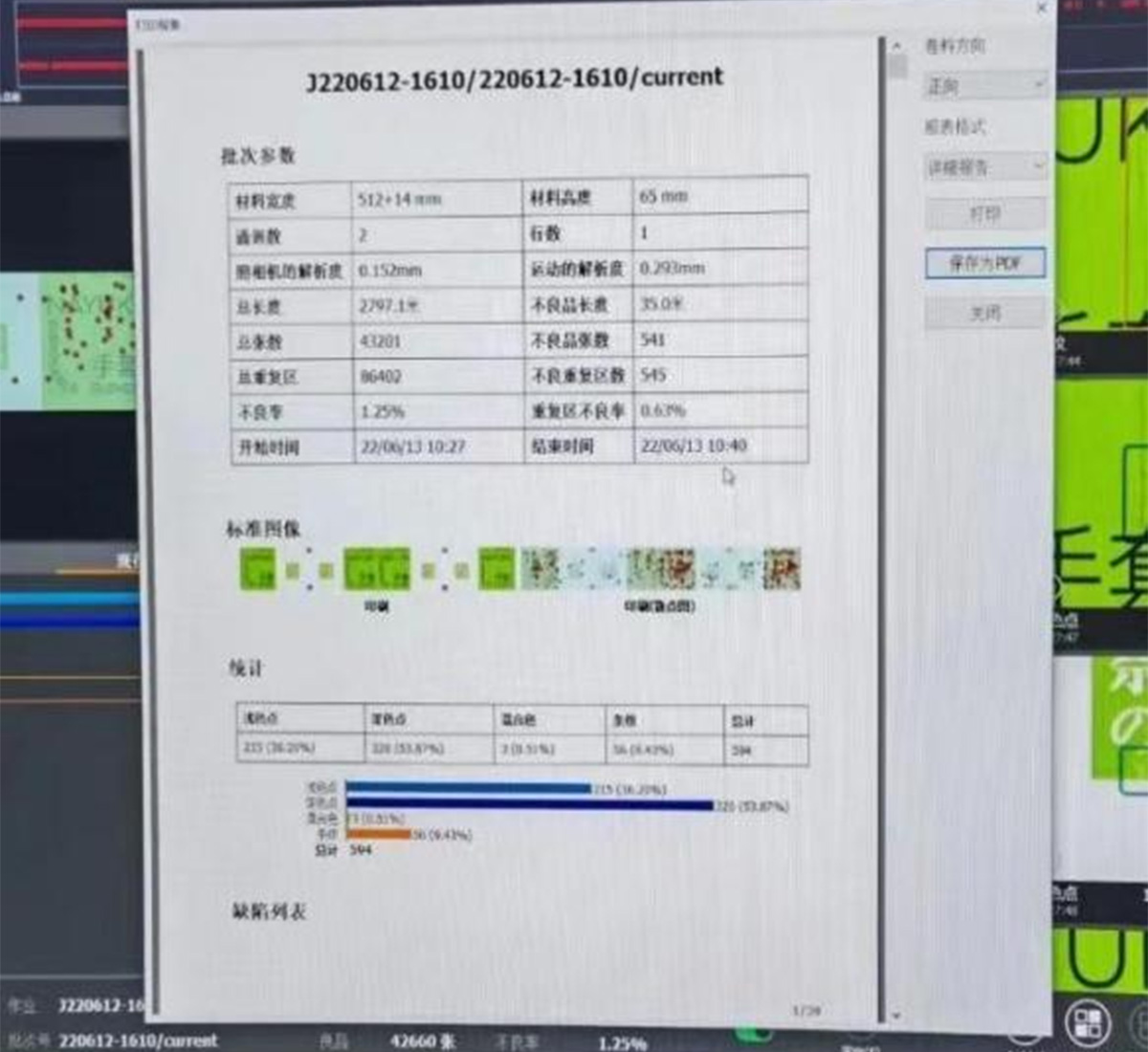

8.All the defects data will be save and you may output a PDF for them any time.

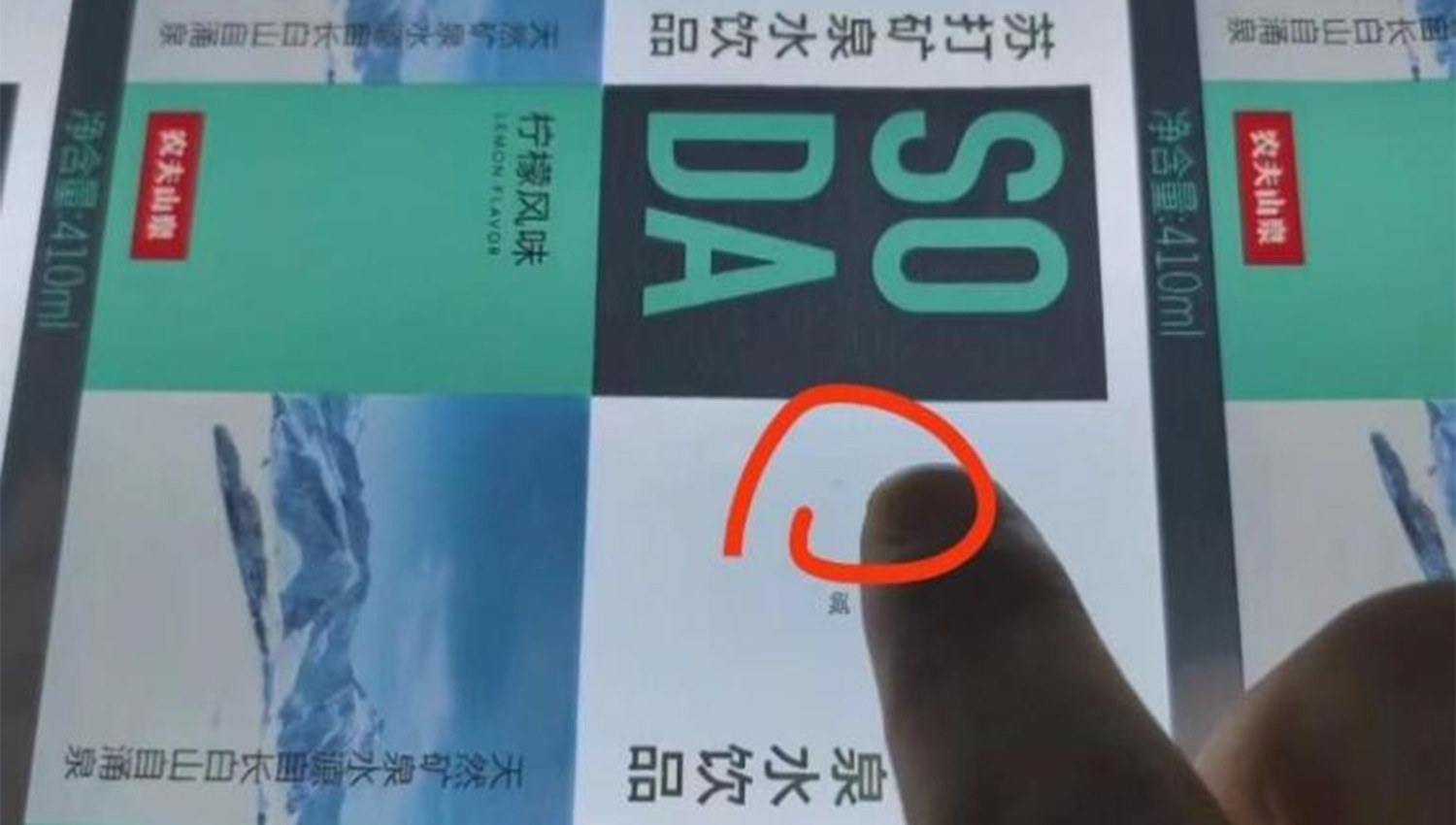

Some sample defects for reference:

-

Blowing film machine testing system

-

Offline high-speed detection - Kesheng machine platform

-

Online detection - Beiren printing machine - Vietnam

-

Bag making machine detection - rejection solution

-

Detection system on the slitting machine

-

Milk Tetra Pak packaging inspection

-

Bag-making machine detection and rejection plan 2

-

Bag-making machine detection and rejection plan 3

-

Double-sided workstation - Kesheng machine