- (1) Structure: both sides folded at the same time single-side adjustable

- (2) Adjustment: manual adjustment

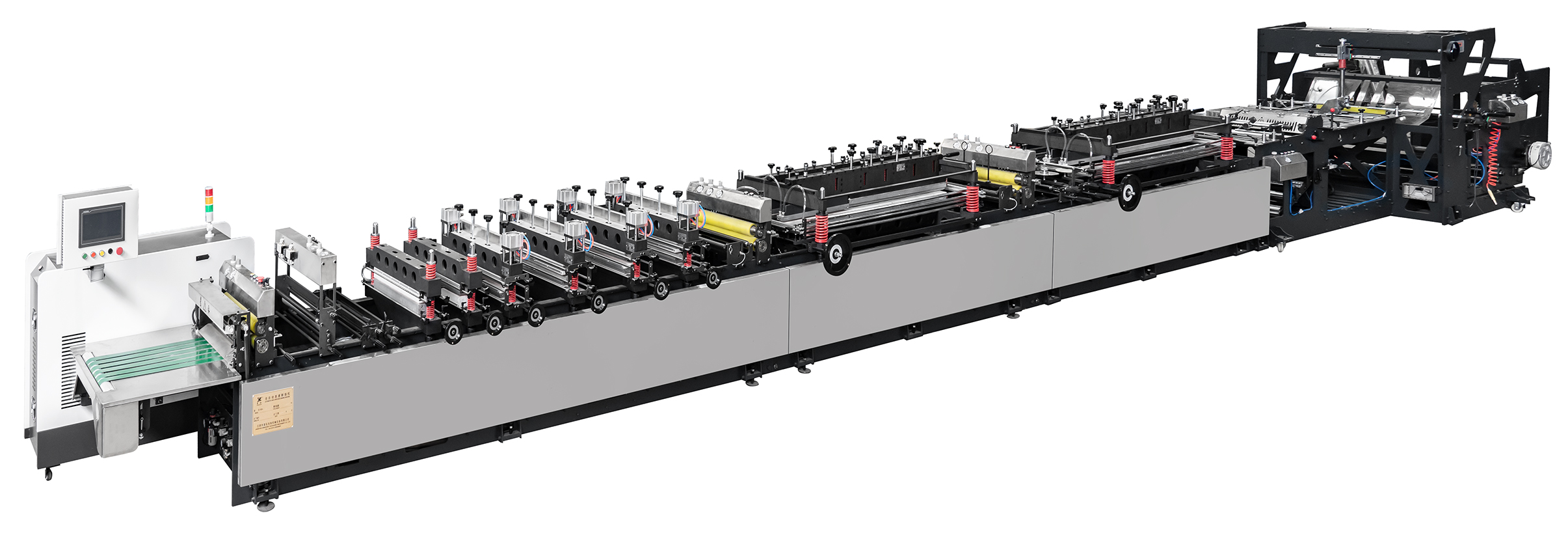

1. Machine form: middle seal, four side seal, two servo, back insert edge, host servo, PLC centralized control model

2. Applicable substrate: BOPP, CPP, PET, nylon and other composite film, multi-layer co-extruded film, pure aluminum, aluminized composite film, paper-plastic composite film.

3. Mechanical maximum beat: 200 points. Normal bag-making time: 120 times/min

4. Maximum discharge line speed: ≤50 m/min

5. Bag size:

Width 60-600mm

Length 60-500mm (double feed function)

6. Sealing width: 6-40mm

7. Bag type: medium sealing bag, four side sealing bag

8. Maximum size of material roll: diameter 800×1250mm

9. Positioning accuracy: ≤±1mm

10. Heat sealing knife:

longitudinal heat sealing 1 group, longitudinal cooling 1 group

Two groups of plastic heat seal and two groups of plastic cooling

Lateral heat seal 4 groups, lateral cooling mechanism 2 groups

11. Quantity of temperature control: 14 channels

12. Temperature control setting range: normal temperature -360℃

13. Machine power: 40KW

14. Overall dimensions: L11520×W1750×H1815

15. Net weight: about 4500KG

16. Color: main body gray, stainless steel tube cover

17. Noise ≤ 75db

1. Unwinding rack device:

Structure: horizontal automatic trimming and discharging mechanism

a. Release material tension control:

(1) magnetic powder brake constant tension brake

(2) Discharge active traction mechanism, frequency conversion uniform discharge

(3) Control mode: floating pendulum rod displacement sensor set unwinding speed

(4) Discharge gas expansion shaft

(5) Discharge pneumatic feeding

b. Correction mechanism control:

(1) Structure: the winding frame moves horizontally

(2) Drive: the correction controller drives the correction driver

(3) Transmission: joint bearing connection

(4) Control form: reflective photoelectric sensor detection, deviation correction controller control

(5) Tracking accuracy: 0.5mm

(6) Adjustment range: 150mm

- (1) Structure: longitudinal arrangement of hot pressing, cooling to close the spring pressing mechanism

- (2) Drive: the main motor drives the eccentric linkage vertical movement

- (3) Quantity: heat seal 1 group, cooling 1 group

- (4) Length: heat seal 800mm, cooling 480mm

- (1) Structure: longitudinal arrangement of hot pressing, cooling to close the spring pressing mechanism

- (2) Drive: the main motor drives the eccentric linkage vertical movement

- (3) Quantity: Shaping 2 groups, cooling 2 groups

- (4) Length: shaping hot seal 540mm, cooling 400mm

- (1) Structure: transverse arrangement of hot press assembly type spring pressing structure, cooling assembly

- (2) Drive: the main motor drives the eccentric linkage vertical movement

- (3) Quantity: heat seal 4 groups, cooling 2 groups

- (4) Length: 640mm

- (1) Structure: pneumatic roller pressing friction type

- (2) Drive: full digital AC servo system

- (3) Transmission: synchronous belt and synchronous wheel

- (4) Control form: PLC centralized control, synchronous fixed length and intermediate tension control Seven. Intermediate tension

- (1) Structure: crank rocker push-pull connecting rod structure

- (2) Drive: servo drive servo motor

- (4) Control form: PLC centralized control

- (3) Transmission: main drive servo motor with 1:10 planetary reducer

- (5) Movement mode: the main motor operation drives the vertical movement of the frame

- (1) Detection method: reflective photoelectric sensor tracking detection

- (2) Detection accuracy: 0.01-0.25mm

- (3) Comprehensive positioning accuracy :≤0.5-1mm

- (4) photoelectric search range: ±3mm

- (5) Correction compensation range: ±3mm

- (6) Positioning correction mode: servo tracking current compensation

- (1) Detection method: Thermocouple detection (K type)

- (2) Control mode: PLC centralized control, PID regulation, solid-state relay drive

- (3) Temperature setting range: normal temperature -360 degrees

- (4) Temperature measurement point: the middle of the electric heating block, to maintain stability and uniformity

- (1) Structure: upper cutter + adjusting device + fixed lower cutter

- (2) Form: spring cutter

- (3) Transmission: the main motor drives the eccentric mechanism up and down

- (4) Adjustment: horizontal movement (both ends)

- (5) Quantity: 2 pay

- (1) Working mode: automatic reciprocating

- (2) Winding method: sheet plate (Note: no paper core method)

- (3) Quantity: 1 set

- (1) Structure: bow type support pneumatic mechanical guide mould impact structure

- (2) Control mode: PLC centralized control

- (3) Drive: relay drive solenoid valve

- (4) Number of punching seats: 2 sets of punching frame, 1 set of diamond holes

- (5) Cylinder: Taiwan Airtek

(1) Transverse knife:

10mm x 4

20mm x 3

30mm x 2

40mm x 2

50mm x 2

(2) Additional knife:

10mm× 2

20mm× 2

30mm x 2

(3) Longitude knife:

10mm x 1

- Power supply: three-phase 380V, ±10%, 50HZ five-wire system

- Capacity: 40KW

- Air source: Pressure ≥0.6Mpa 35m/min

- Cooling water: 3 L/min

(1)PLC Panasonic AFPXH-C40T, TR8, DA2 Or Panasonic AFPXH-C60T, TR8, DA2

(2) Interface Weinview 10-inch

(3) The host Modoli planetary reducer with Panasonic 4KW servo

(4) Cutting tool Panasonic or Delta 1KW (cut), Panasonic or Delta 0.75KW (shift)

(5) Traction Panasonic 1.5KW servo motor with driver (Note: a total of 5 sets)

(6) Discharge gear motor made in Taiwan with Inovance 0.4kw frequency conversion

(7) Delivery of 1:10 gear motor made in Taiwan

(8) Correction Suzhou Yintong 130 motor with Wuxi precision control correction controller

(9) Magnetic powder brake Wuxi Bolis 5KG with constant tension control (discharge)

Wuxi Bolis 0.6KG with constant tension controller (independent)

(10) Photoelectric sensor Panasonic SUN LX-111 photoelectric sensor Wenzhou BTG Optoelectronics (material release)

(11) Solenoid valve Taiwan Airtec DC24V

(12) Switching power supply Taiwan Delta

(13) Electrostatic eliminator Shunde Junyu intelligent industrial control or Wuxihuaso electrostatic technology

(14) Proximity switch Wenzhou BTG NPN

(15) Heating module Changzhou Huibang

(16) Solid state relay Delixi

(17) Relays Siemens or Schneider

(18) Encoder Wuxi Xinya Electronics

(19) Button switch Shanghai Tianyi

(20) Air switch Chint or Delixi

(21) Contactor Chint

(22) Ultrasonic Guangdong Red Sun

(23) Pneumatic components Taiwan Airtac

Quotation: Contact us

INCOterm: FOB Shanghai

Payment: 30%deposit and 70% balance before delivery

Production Lead time: 30 working days

Loading port: Shanghai

Warranty: 1 year for the machine